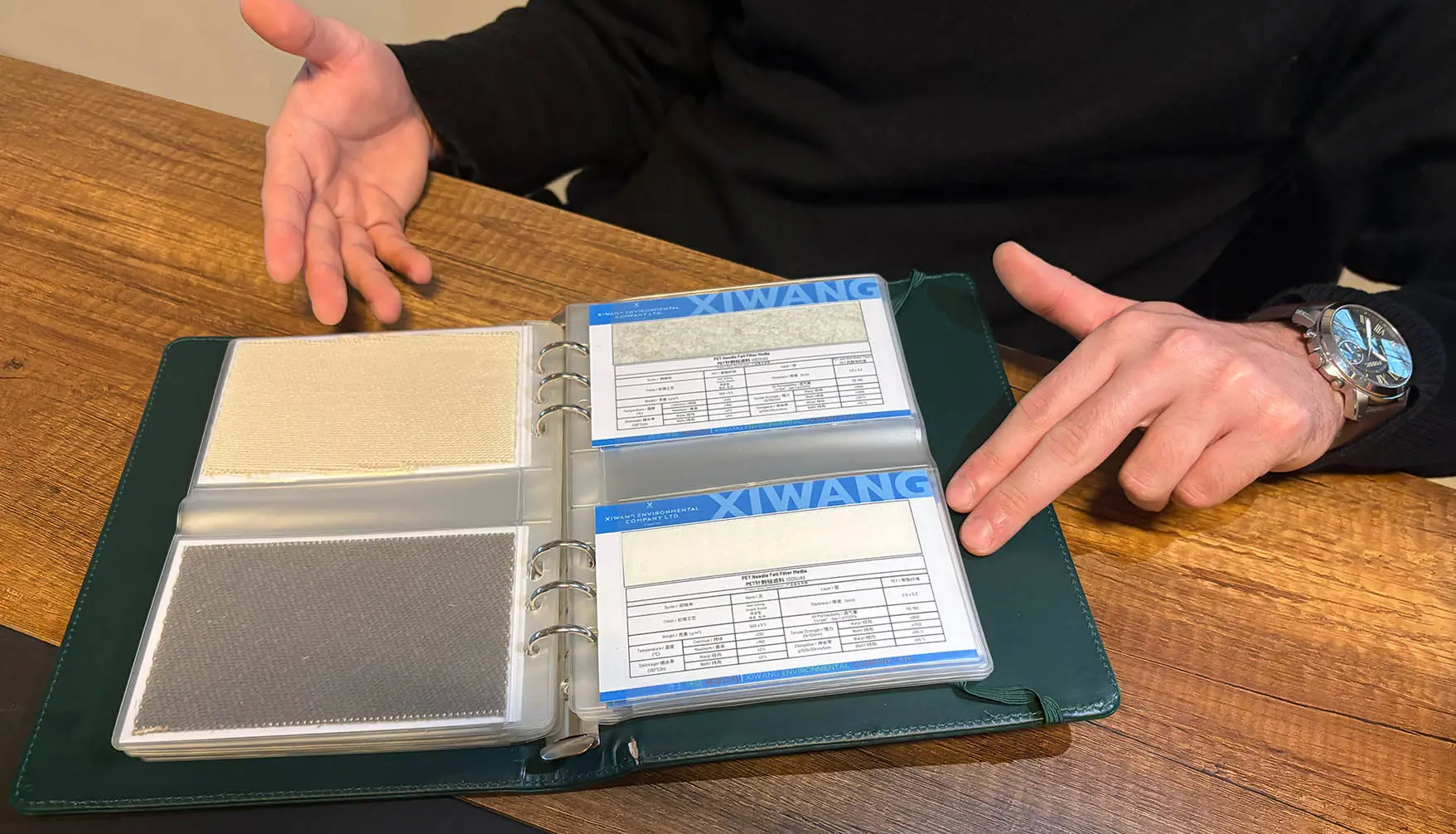

As Xiwang Filter, we provide comprehensive analysis and testing services with a modern laboratory infrastructure and expert staff to ensure product quality and maximize process efficiency. In our application and R&D laboratories, we evaluate every stage—from new product development to failure analysis of end-of-life filter media—using scientific methods, and in collaboration with BWF Distic, we deliver data-driven optimization solutions to our customers.