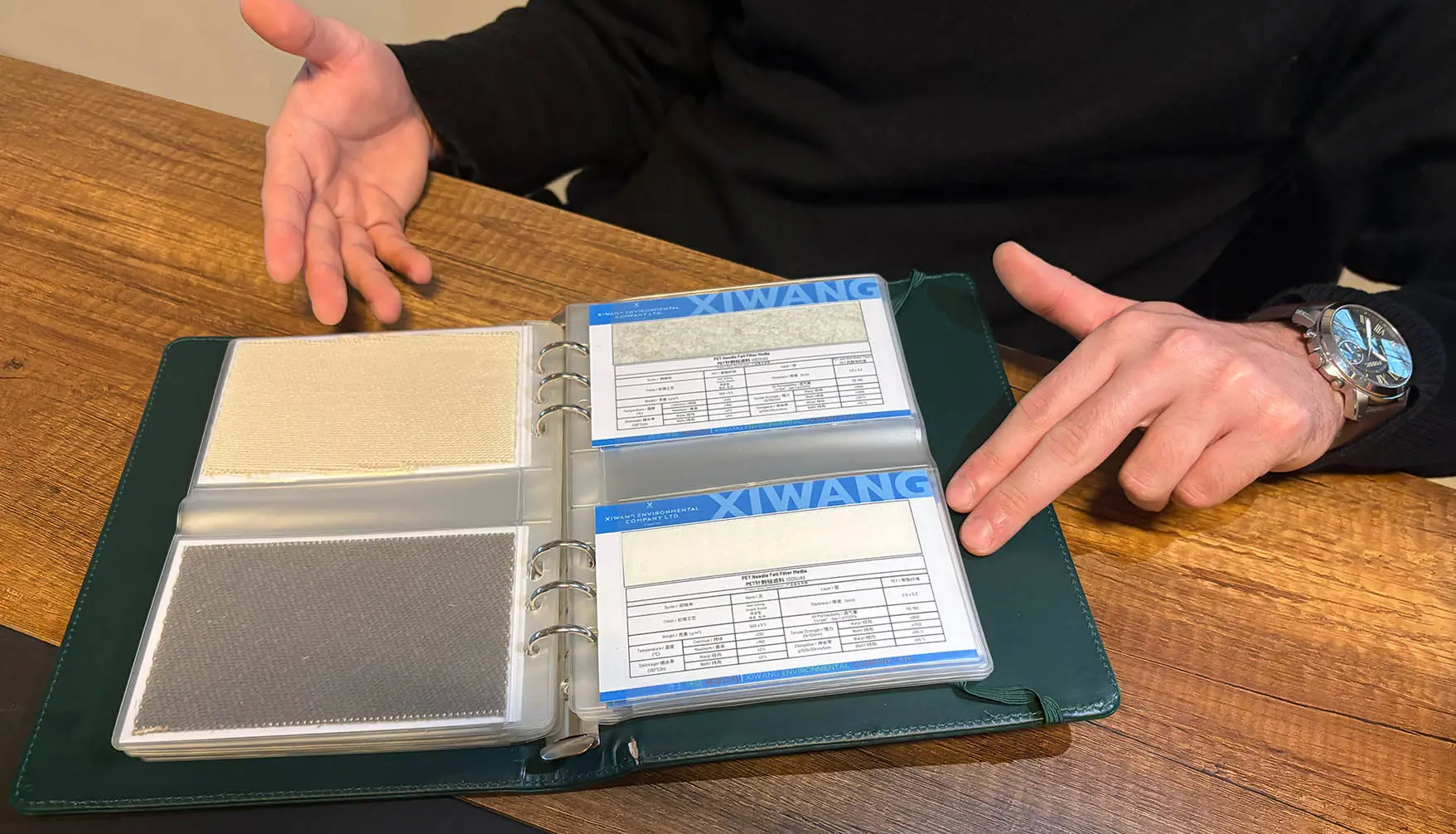

Each facility has different dust characteristics, temperature profiles, production regimes, and maintenance cultures. For this reason, we manage all pre-sales and after-sales activities using customer-specific data files. Information such as visit notes, performance measurements, installed filter types, and maintenance history is consolidated into a single file—allowing us to start every new requirement based on concrete data rather than from scratch.