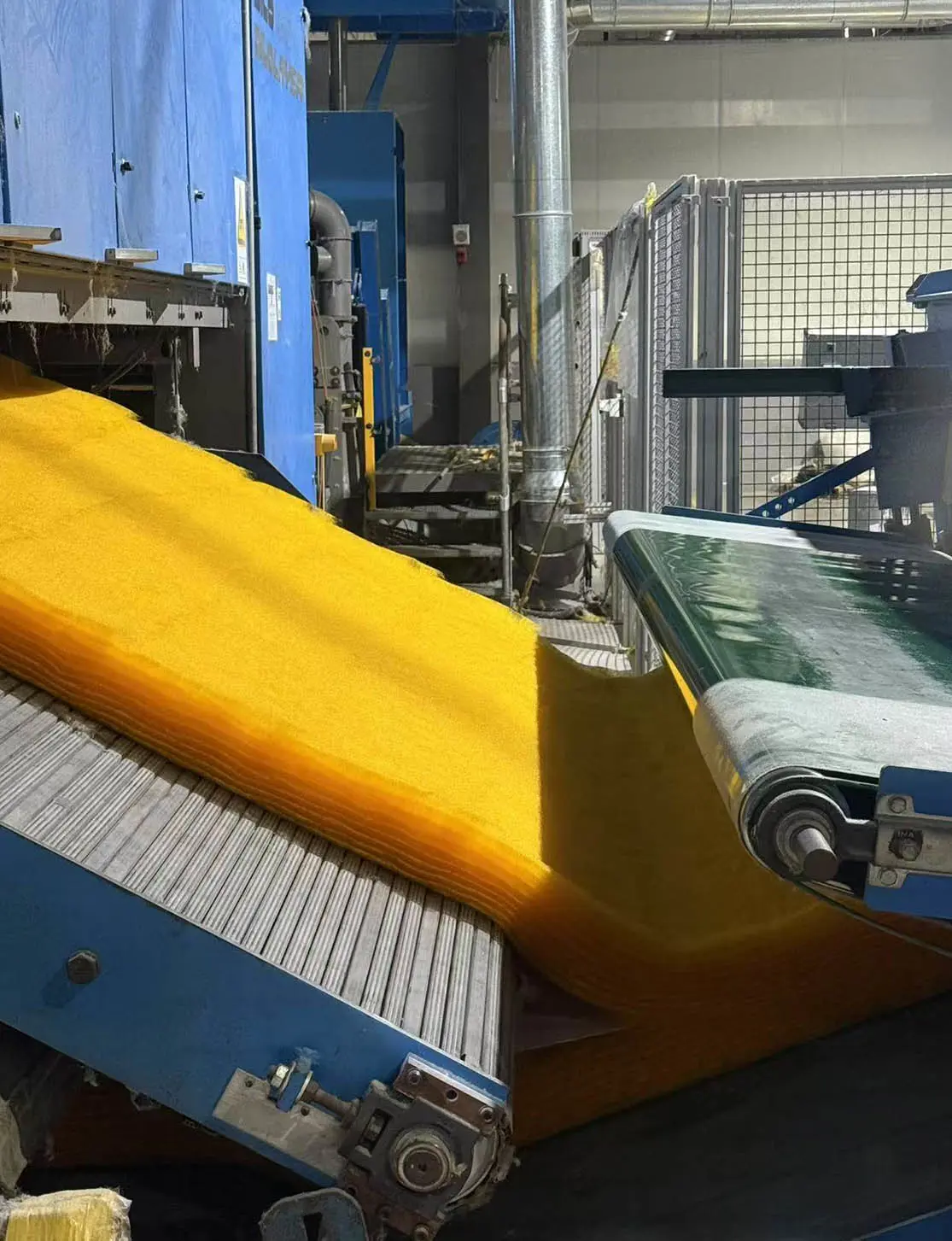

With the expertise of Xiwang Filter and the engineering support of BWF Distic, we deliver low-emission, high-efficiency filter bags manufactured in accordance with American and European standards. By applying strict quality control at every stage of the production process, we develop long-lasting and reliable filtration solutions suitable for heavy industrial applications. In doing so, we strengthen your environmental compliance, increase operational efficiency, and reduce your total cost of ownership.